Beauty in the world amidst the global chip shortage

The pandemic-induced global chip shortage made the Teensy 3.2 micro-controller unavailable. PJRC, Manufacturer of Teensy, does not expect the supply of MK20 chips made by NPX to ever recover. The newer Arm Cortex-M7 on the Teensy 4.0 does appear to be recovering, but it is still questionable, and would require a complete redesign to incorporate into Apollo’s motion controller.

The pandemic-induced global chip shortage made the Teensy 3.2 micro-controller unavailable. PJRC, Manufacturer of Teensy, does not expect the supply of MK20 chips made by NPX to ever recover. The newer Arm Cortex-M7 on the Teensy 4.0 does appear to be recovering, but it is still questionable, and would require a complete redesign to incorporate into Apollo’s motion controller.

Parallax, a Californian company produces a micro-controller made in the USA which doesn’t have supply chain issues, and has been chosen as the replacement micro-controller for Apollo’s motion controller, the Parallax Propeller.

Parallax Propeller

It has 8 cores which run simultaneously, allowing it to read data from the Pi and send signals to the stepper drivers at the same time. It’s not very easy to program, nor is it very fast, both of which help it to stay available in these tough times.

It’s available in this giant form factor, and a more standard SMD package with about 20,000 units in stock.

Propeller Project Board

We did the initial programming work using a Propeller Flip board, which has a similar shape to a Teensy. Subsequently we prototyped the motion control board using Propellers Project Board, available for about $17 on their website. Parallax.com

Here we connected some opamps to the propeller to interface it with Apollo’s stepper motor drivers, along with adding inputs for Limit Switches so Apollo could home itself.

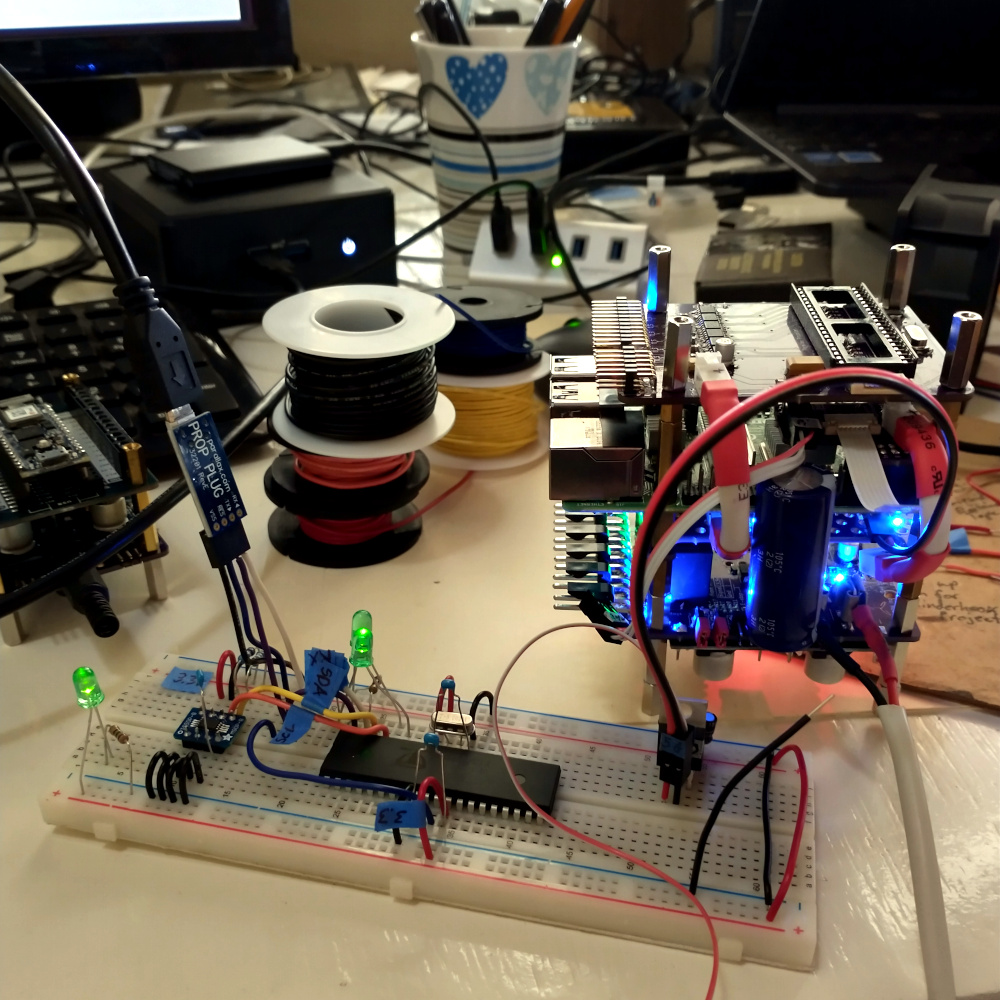

Prototyping on a Breadboard

To prototype the propeller chip before ordering a printed circuit board of our own design, we used a bread board and tested out all the components which come pre-installed on the Proppler Flip and Project Board we had used. These included a 3.3v regulator for the propeller, a crystal oscillator, and an EEPROM module. Once assembled, it was test programmed with the Prop Plug sold by Parallax.

Apollo's pcb stack

Sideways

Powered Up

The trough-hole prototype made on the Propeller Project board was hooked up to a Raspberry Pi and tested. With a little development, it was soon moving the arms on Apollo as the Teensy had been. The major difference, Propeller chips are available to purchase...

Once tested, we ordered printed circuit boards with the same basic design from OSHPark. Assembled with components from Digikey, and successfully tested it again.

During the assembly / testing process, we hooked a QA100 oscilloscope up to the 24v power supply board to see if its soft-start circuitry was tuned correctly. The components pictured charge the capacitor on this board through the big green 3ohm resistor for about 0.2 seconds, until the capacitor is about 2/3 full. Then it switches on a large mosfet, allowing the full flow of electricity from the main power supply into this 24v power supply board. Before adding in the soft start, we ran into many broken power supplies from the large capacitor filling too quickly.

The Race Track at Crofts Hill Jamaica’s Annual Independence Day Donkey Races

Looking towards the starting line

Looking over the finish line